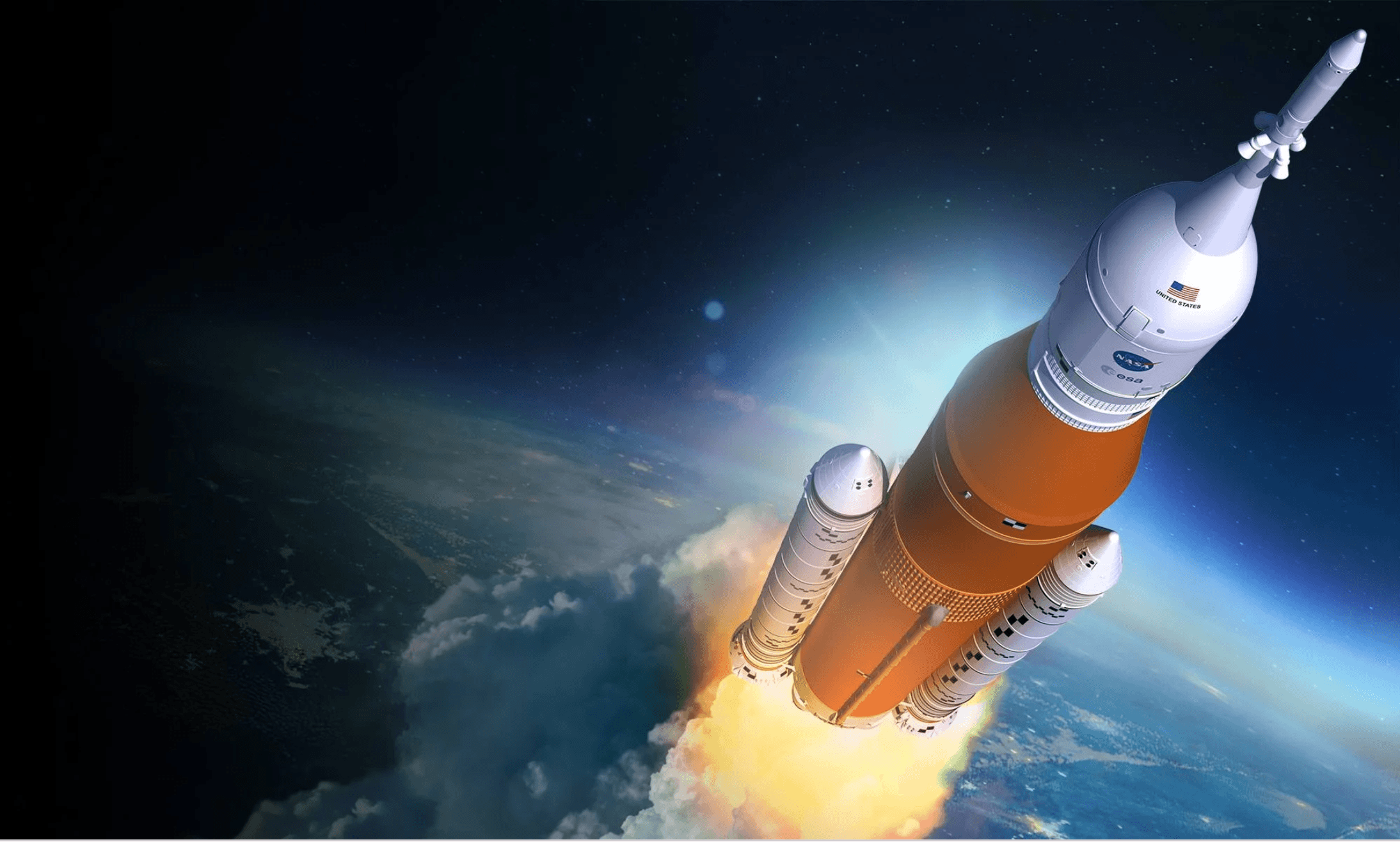

One of the two huge tanks that will fuel NASA’s Space Launch System completed final welding on the giant Vertical Assembly Center at New Orleans’ Michoud Assembly Facility, marking an important milestone for the journey to Mars.

“Boeing is building big rockets again,” said Boeing SLS production leader Jackie Nesselroad. “It’s an exciting time to be part of the NASA team.” The Space Launch System will be the largest rocket ever built, capable of carrying crew and cargo into deep space.

The tank is a confidence article, which verifies weld quality, and it now moves on for thermal protection foam application, which will protect the tank in temperature extremes during launch. It’s this foam that gives the rocket its orange color.

Towering more than 200 feet tall with a diameter of 27.6 feet, the Space Launch System core stage is designed and built by Boeing. It will store cryogenic liquid hydrogen and liquid oxygen that will feed the vehicle’s RS-25 engines on the rocket’s first flight in 2018- Exploration Mission 1 (EM 1). EM 1 will test integrated rocket and crew capsule systems before a follow-on crewed flight, Exploration Mission 2.

All welding for the SLS core stage for the Block I configuration of the rocket – including confidence, qualification and flight hardware – will be completed this summer.